| « |

September 2025 |

» |

|

| S |

M |

T |

W |

T |

F |

S |

|

1 |

2 |

3 |

4 |

5 |

6 |

| 7 |

8 |

9 |

10 |

11 |

12 |

13 |

| 14 |

15 |

16 |

17 |

18 |

19 |

20 |

| 21 |

22 |

23 |

24 |

25 |

26 |

27 |

| 28 |

29 |

30 |

|

The Dog Blogs

Tuesday, 30 August 2005

improve shop efficiency by 15% (from fleetmag)

Active Supervision Improve shop efficiency by 15 percent By Joel Levitt Contributing Writers Sometimes the simplest cures to big maintenance shop problems create the biggest results. Active supervision, for example, can improve shop productivity by 15 percent. It is essential that the direct supervisor of mechanics have a significant amount of their time available to cruise the shop floor. The question is, what is active supervision? Active supervision takes place when the supervisor spends substantial time on the shop floor helping workers solve problems. As strange as it might sound, on the psychological level, the supervisor might have to be both mother (nurturing and supportive) and father (strict and tough) to members of the crew. Active supervision is broken into several dimensions: Ongoing performance monitoring. The supervisor knows how long each job should take and checks it periodically throughout the day. A four-hour job should be half done by break. When the jobs fall behind the experienced supervisor thinks about the best intervention. In some cases it might be logistical help, tool help, information about how to precede, in some cases a kick in the pants! In other cases the supervisor will hang back if wrestling with the job is important for training. Personnel booster and ombudsman. The supervisor is the representative of the company to the shop personnel and frequently represents the workers to management. He or she should be a ceaseless booster of the mechanics' interests. The supervisor should be the one to go to bat with Human Resources on behalf of one or his or her people. Paperwork compliance goon. The accuracy of all analysis is derived from the work order. If the work order is complete and accurate then decision making is dramatically easier. The supervisor is always auditing paperwork and returning it when it is deficient. He or she should always look at work orders on the floor and ensure that entries are being made contemporaneously (at the same time) as the activity. The supervisor should also ensure that closing comments are complete enough so that a year from now they will be meaningful for further analysis. Scheduling czar. Shop time has to be scheduled to optimize the use of scarce resources while serving the customers. While there might be a separate person scheduling a large shop the supervisor should have significant input. Teacher and mentor. The supervisor should be training, or directing the training, of members of the crew. Everyone has areas that they are better at and areas that they are worse at. The easiest crew to schedule is one where everyone can do everything. The effective supervisor should be reviewing the schedule every day and looking for training opportunities. These can be formal training sessions or letting the trainee'help' an experienced hand. Quality control officer. The supervisor is responsible for the overall quality of all work performed in his or her shop. Where there are quality issues the supervisor determines the cause of the problem (which could be in several areas: lack of knowledge or skill; lack of aptitude; lack of adequate physical strength or dexterity; bad attitude; lack of the right tool; lack of the right part; some inadequacy in working conditions; inadequate time; preoccupation brought about by a problem outside of work). The supervisor works with the worker to solve the quality problem. If the problem is with the company or system (such as bad working conditions, or a lack of tools or parts) he or she should attack that, too. If the worker has a problem with external issues the supervisor should mentor that person or find help for him or her within the organization. Safety officer. The supervisor should intervene any time an employee or visitor performs an unsafe act or is in the shop without personal protective equipment. The supervisor is the champion for safety and makes sure the shop is safe. Tidiness cheerleader. The shop must be kept clean for safety, efficiency and morale reasons. All clean-up for individual jobs should be part of and charged to the individual job. The supervisor should arrange for periodic clean projects to keep the whole area and the yard tidy. Of course, there are scores of other essential roles. These include Psychiatrist, mother, father, friend, and confessor (at least). Is there any better job?

Posted by DogHouse

at 7:39 PM EDT

Monday, 15 August 2005

Idle Timer

Mood:

irritated irritated

A comment I overheard by a driver today really chapped my ass........... the drivers bus had shut off due to the Low Idle Shutdown feature, and as I was walking away from restarting it I heard the driver say to someone "the is the stupidist thing I have ever seen, Greyhound is probably spending a fortune on those things and they aren't nothing but trouble."..........Well, here's the deal.....what Greyhound is spending a fortune on is Diesel Fuel......... Over a million gallons a year of which are from engines idling unnecessarily......... They do not spend a fortune putting idle timers on the coaches because they were all made with the idle timer in place already........the idle timer is a feature in the engines ECM, and it is simply turned ON, or activated......... What this means is it wasn't Greyhounds idea to have idle timers shut engines off after they are left at idle.......... The idle timer is from the factory on all DDC engines....... Most all over-the-road transportation companies use them........ the idle timer saves hundreds of thousands of dollars in fuel and unneccessary engine wear, as well as other component wear........... Idling isn't the perfect conditions for those engines anyway........ Going 70 mph, at 180 degrees, with 55 people and a belly full of luggage is when that engine is at it's happiest, and that is what that DDC Series 60 is made for........ when it isn't working hard, it would rather be sitting still, not wasting it's life and power idling............. But through all the bitching I hear about the Low-Idle shutdown feature......the question I never get tired of asking a driver is, "why don't you just make sure the fast idle is on??????????????? It is called the Low-Idle shut down feature for a reason.......because it only shuts the engine off if it is on low-idle.........if it is on fast-idle, it will not shut off..........Now, that being said, checking to make sure the fast-idle is on is slightly more difficult than just looking over at the switch to see if it is pushed up....you may actually have to push the switch off and back on again to engage the fast-idle.......I know, I know, that is difficult for a driver......sometimes I wonder how drivers manage to get both shoes tied, but anyway........it isn't that hard to turn the fast-idle switch off and on again, and you will hear the difference in engine sound between low-idle and fast-idle...........Remember, the low-idle shutdown feature only works when the coach is parked with the park brake applied, transmission in neutral, and the fast-idle switch OFF.......also remember, if your coach is parked more than 10 minutes, you should shut it off anyway...........

Posted by DogHouse

at 4:10 PM EDT

Wednesday, 15 June 2005

More on Training

The following link is another article in regards to training..... I hope that someone that reads this will email it to the Maintenance departments upper managment........ Valuing Training

Posted by DogHouse

at 7:51 PM EDT

Updated: Wednesday, 15 June 2005 7:53 PM EDT

Tuesday, 7 June 2005

G45 Left Front Service door won't close ???

Everyone has seen the G45 front left service door with tape or GPX envelopes all over it because "it won't stay closed." That looks just like shit when drivers do that, and it usually isn't neccessary.

I am going to tell you how to shut that door properly, but it will involve bending your lazy asses over, maybe even getting down on one knee.

When you open that door, you reach underneath of it and pull a release handle back toward you. Then when you close it, you just slam it. What you need to do is push it closed gently. If it doesn't latch shut, then hold it shut, reach underneath and PUSH the release handle away from you (( the opposite direction of opening it)), this will generally latch it closed. It won't work 100% of the time, but it will work most of the time.

This isn't rocket science folks. Quit putting tape and shit all over the bus. It is very hard to clean off, and looks like crap. The G coach may be a piece of crap, but at least it looks good. Or LOOKED good until GLI drivers got a hold of it.

Posted by DogHouse

at 11:39 PM EDT

Sunday, 29 May 2005

Motor Brushes

Mood:

on fire on fire

Attention Fools...... when you replace blower brushes, you replace all of them, not some. Yes, sometimes you can get a motor to run by replacing one or two of the brushes. But it will only run long enough to get the bus out of your hair. Then it will go roadfail again somewhere else. Everyone wants to bitch about not making enough money, not having good enough benefits, not having new equipment....the reason why is because the company doesn't have the money to hand us, stupid shit like this is why. Maintenance costs are high because of fools that do things like replace two out of four brushes. Roadfailures are expensive. We are here to prevent roadfailures , not cause them. If a motor has 4 brushes, replace all 4, if it has 2, then replace both. You are already in there working, so why not go on and do it right. Case in Point, the coach that failed at our location today, no a.c., condensor motor inop, 2 brushes were like new, 2 were old and worn out. I replaced all 4, it took about 20 minutes. I won't name the location that made the repair, but it is one of those that is always getting free pay checks. There is no good reason for half assing a condensor motor brush replacement. The only reason is laziness. And stupidity. The thing that really burns my ass is that in their MCMS comments, the mechanic says he replaced all four. A bold faced Lie. Is there anything in the world worse than a Lazy Liar ?? Is there any pride left in the world ?

Posted by DogHouse

at 8:24 PM EDT

Updated: Sunday, 29 May 2005 8:27 PM EDT

Sunday, 22 May 2005

Maintenance Training

Dear Upper Maintenance Management..... Please, Please, Please read this article...... How to find and nurture quality technicians

Posted by DogHouse

at 5:30 PM EDT

Updated: Saturday, 28 May 2005 5:41 PM EDT

Sunday, 1 May 2005

Reducing Roadfailures

Mood:

a-ok

Want to reduce roadfailures and downtime ????? a-ok

Want to reduce roadfailures and downtime ?????

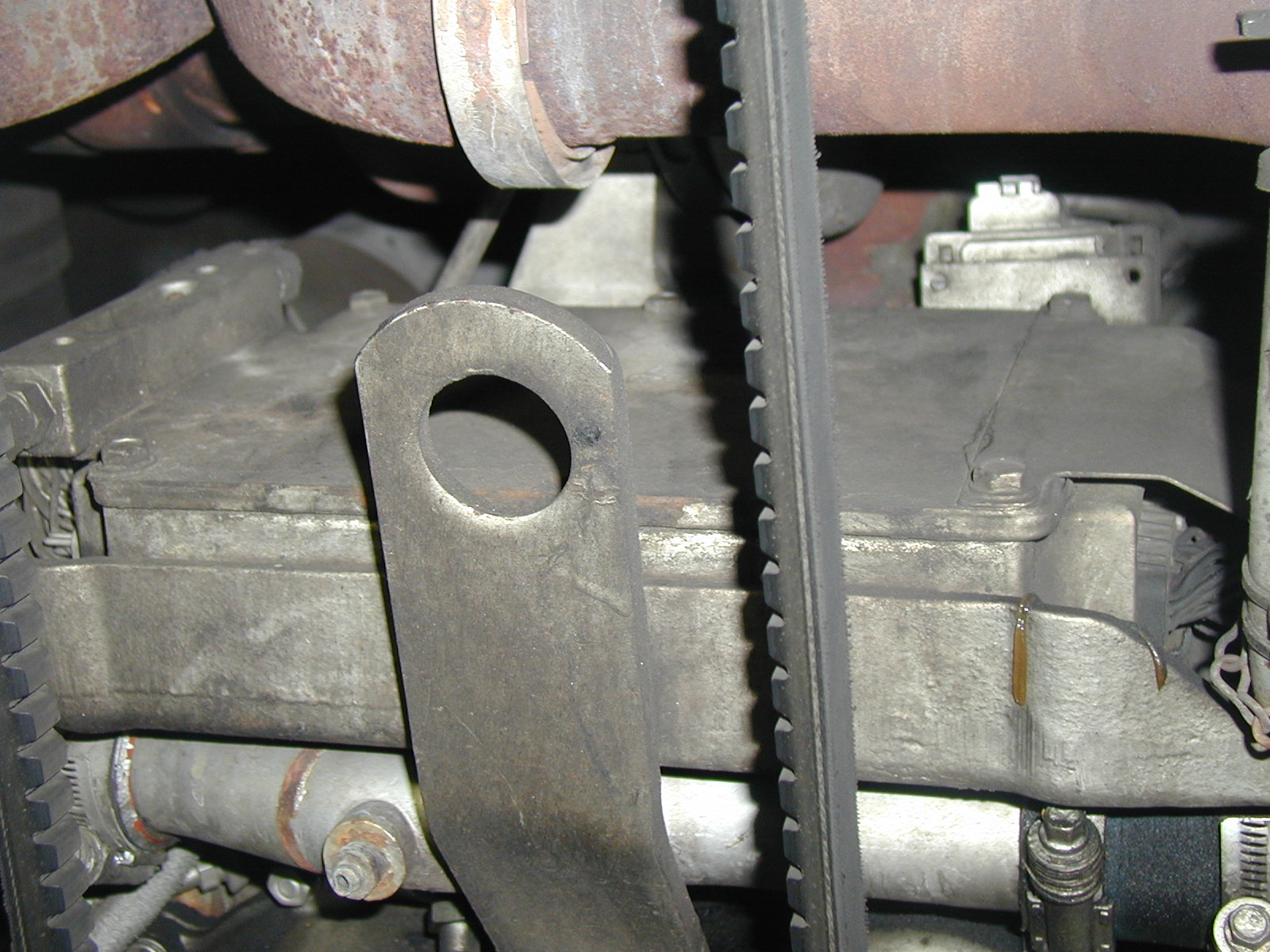

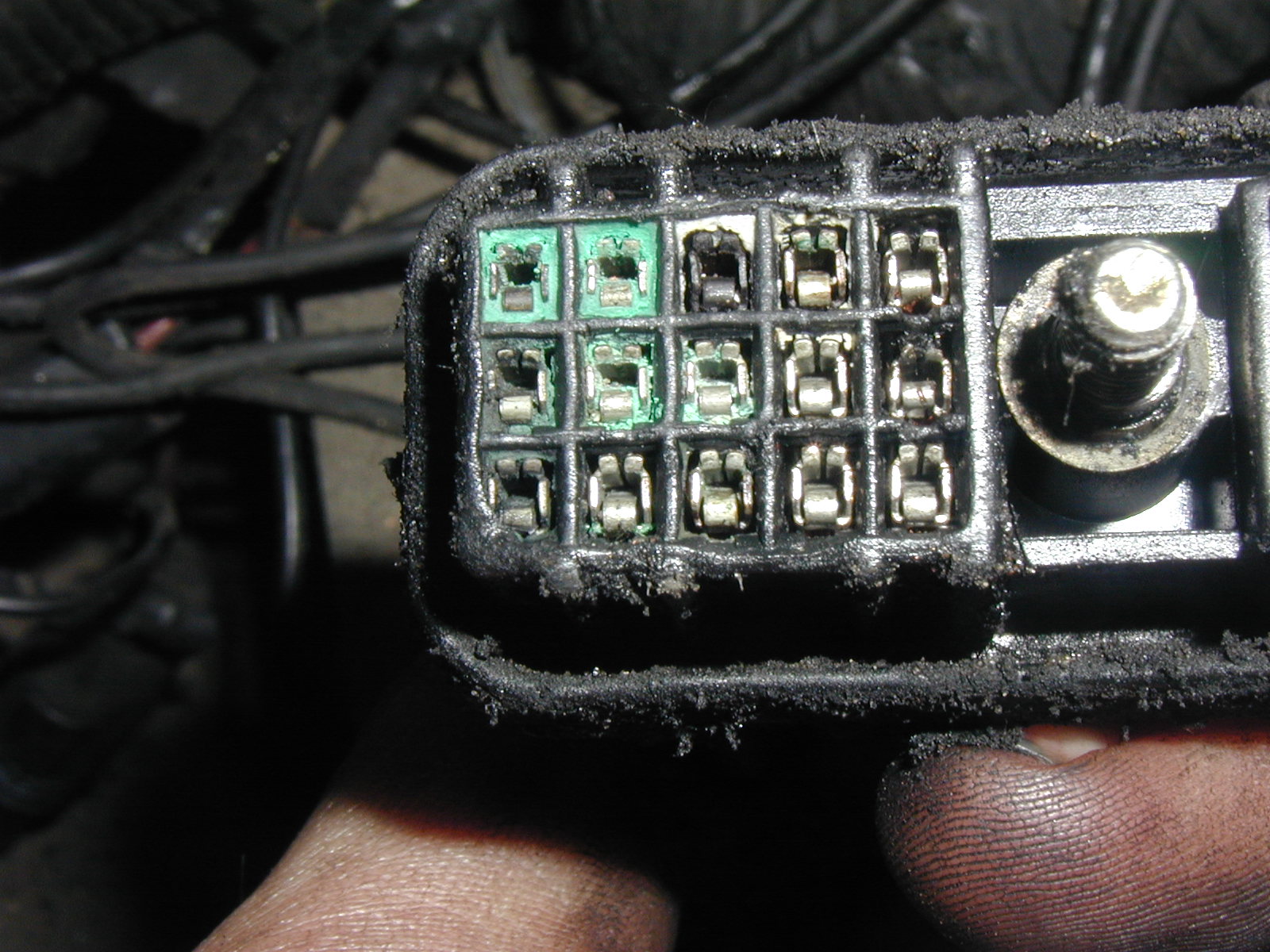

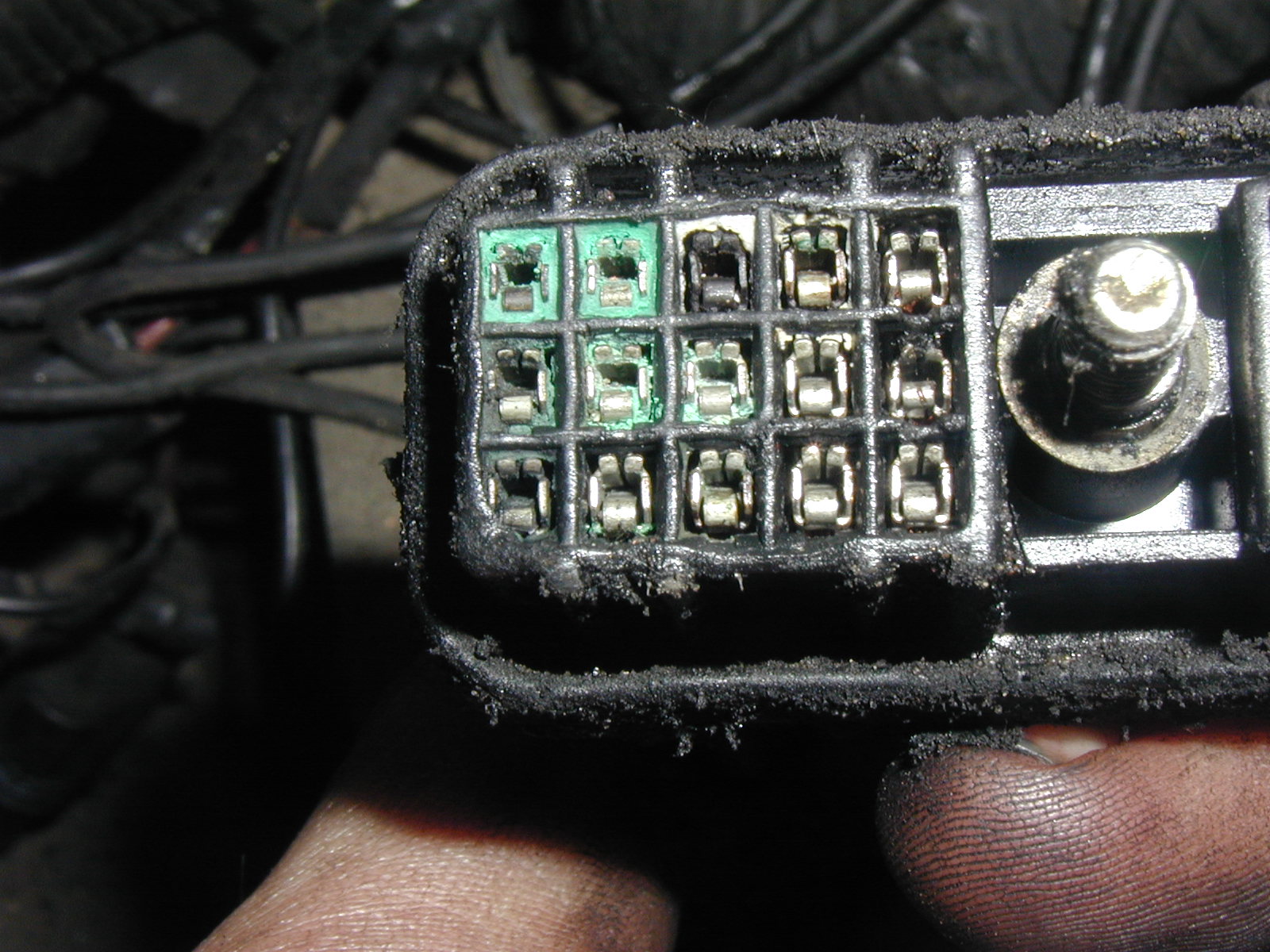

Well, how much downtime, and how many roadfailures are due to problems at the Engine ECM harness connectors ?? A great, great deal I would venture to say. Most of which are caused by corrosion from insulation rubbing, or cuts.

The problem with the ECM on the 6v92's was stupid location. Right under the Turbo Charger. Nice temperatures there....And the harness is constantly rubbing the top of the engine, usually the power steering filler neck.

On the Series 50 and 60 engines, they got bright and moved the ECM away from the Turbo Charger, to a much cooler location, right on the side of the engine, about a foot off the road. This one stays cool, but has constant harness connector and wire corrosion.

These problems do not exist with the Transmission ECU and the ABS ECM. Why ?? Because they are mounted remotely, in one of the baggage bins, in a sealed box. Once in awhile they experience a wiring harness corrosion problem, not nearly as much as the engine ECM.

Why not mount the Engine ECM remotely, and reduce a whole buncha roadfailures and out of service numbers.

Posted by DogHouse

at 6:38 PM EDT

Updated: Saturday, 28 May 2005 5:47 PM EDT

Saturday, 30 April 2005

Maintenance Costs

Mood:

loud

Why are maintenance costs so high??, everyone asks. loud

Why are maintenance costs so high??, everyone asks.

Here is one small example, one of many of the stupid things we do repeatedly....

When a coach has a siezed bearing on a fan gear box, what do we all do for repair ??

Replace the fan gear box. Depending on how you order, a fan gear box can cost from $2000-$3000.

Has anyone ever heard of rebuilding it ??

The parts to rebuild the siezed shaft and bearing will cost about $300 and it is far less labor intensive and not time consuming.

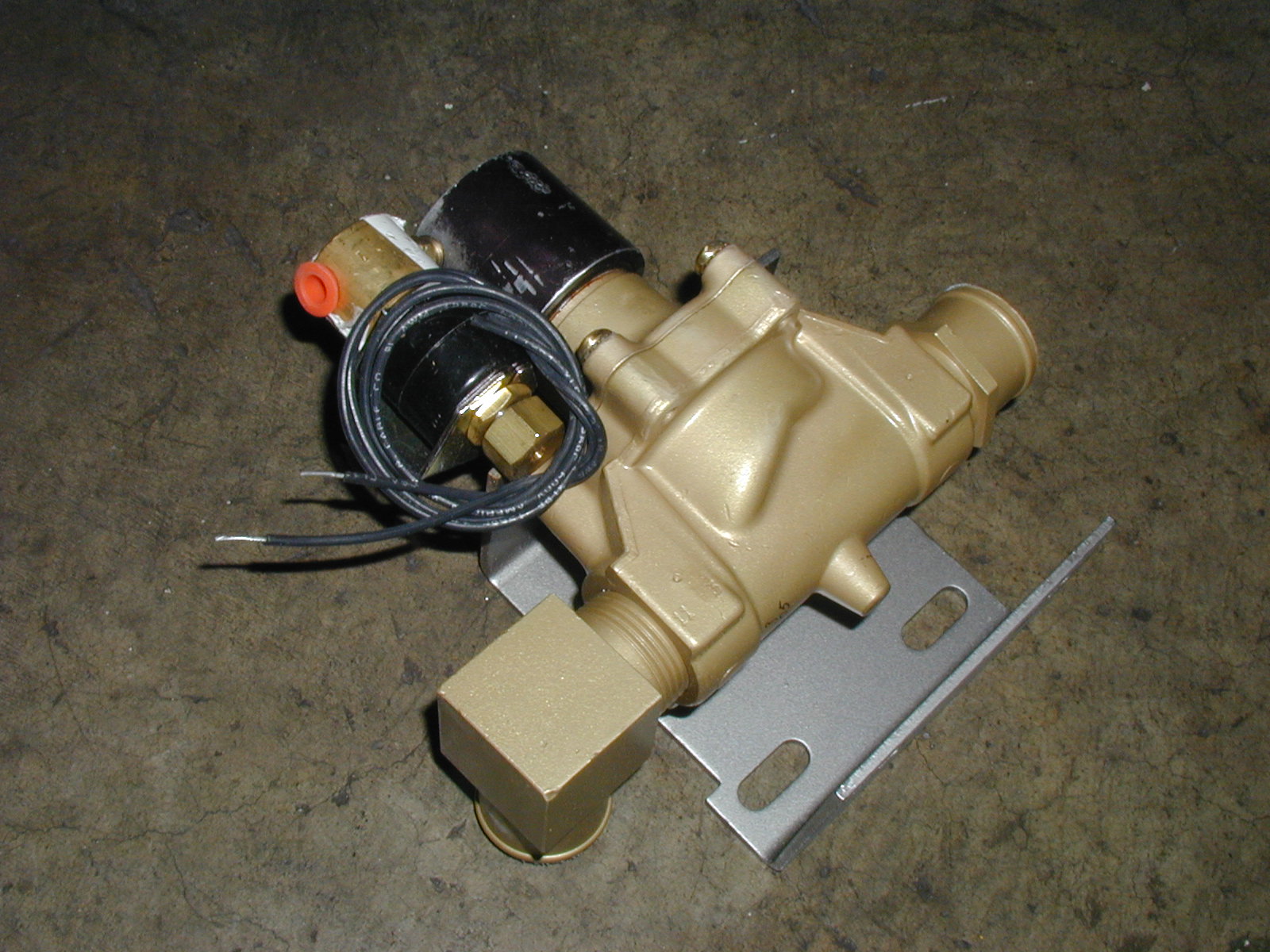

Another thing is Heat Valves. Replaced over and over, when they are rarely the cause of the problem. A heat vavle is a big chunk of brass with a hole thru it. Everything that does all the work can be serviced.

the heat vavle rebuild kit is only $83 while a new heat valve will run you $625. It is not hard, or time consuming. There is about 5 or ten more minutes of labor than what it takes to install a new heat valve. The rebuild kit part number is 16007076.

The brake valves all have an available rebuild kit, as well as purge valves. Pretty much any vavle has a rebuild kit that can make it new again for a fraction of the cost to replace the entire Valve. This is where you can save a lot of money at your garage. Make sure people aren't replacing parts that can be easily rebuilt.

Posted by DogHouse

at 6:12 PM EDT

Updated: Saturday, 28 May 2005 5:49 PM EDT

Friday, 29 April 2005

My bus came straight out of the garage and broke down.

Mood:

not sure

many drivers ask, "why is the equipment in such bad shape, why does it come straight out of a garage broken ??" not sure

many drivers ask, "why is the equipment in such bad shape, why does it come straight out of a garage broken ??"

Well, that's the million dollar question.

Lower Budgets

Smaller active fleet

older active fleet

operator abuse

general maintenance neglect

poor repair of a previous failure

There are 50 million reasons.

One of the biggest problems is the absence of Operator Level Maintenance. That is you, the driver. Driver level maintenance doesn't mean you have to fix anything. Maintenance simply needs you to know what you are operating and properly report problems by doing pre and post trip inspections correctly. Operators, for the most part, don't know the equipment and don't inspect the equipment. There will NEVER be a good fleet maintenance program without knowledgeable, active, driver involvment.

Keep in mind, proper driver inspections are the law.

Regulations 396.11 and 396.13.

The next biggest thing is at least half the mechanics cannot troubleshoot the equipment they are paid to repair. Training has to be established, but it needs more specialized than in the past. Training was done in 2003 with materials from MC-9's and 102A3's There was also some new materials, but not nearly enough. GLI and ATU need to offer financial assistance to contract employees so we can update our own educations as well. Wouldn't that be an investment ??

Generally, most maintenance locations are not concerned with what happens to the piece of equipment as long as it makes it to another maintenance facility before it breaks down.

It isn't all the mechanics fault that your bus breaks down when it came straight out of the garage.

A mechanic cannot predict the future. Some things break completely seperatly of what was just repaired. If your bus just got the brakes fixed, and it road fails for no AC, that is hardly that mechanics fault that just fixed the brakes. And keep in mind, all mechanics answer to supervisors. If the supervisor tells them to put it back in service, then they have no choice. The supervisors only concern is the number of out-of-service. There is NO quality control.

There are some real good mechanics out there in our Fleet. Many that have taught me some good stuff. But I think they are out numbered by the ones that take no initiative to make themselves better. It's time to start learning about Multiplexing, and they are still learning about Basic Electricity.

Our Mechanics and Supervisors should know as much as the people we had as trainers before.

Our trainers should be damn near engineers, and there should be one in every garage.

Our operators should know the equipment like the backs of their hands. And should be given techinical training on that equipment regularly.

you should not have to explain to an operator what the rear engine start switch is, they should know the day they drive their first run. The ignorance of most our drivers is unbelievable.

Maintenance needs to be involved, deeply, with the driver training program.

This equipment should not be out of service so much, but everyone is to blame for it's condition from the head of maintenance to the janitors. The equipment is neglected. Period.

Posted by DogHouse

at 12:28 PM EDT

Updated: Saturday, 28 May 2005 5:55 PM EDT

Thursday, 28 April 2005

D4505

Mood:

d'oh

They say MCI's new D4505 looks like a G-model in front, and a D - model in back d'oh

They say MCI's new D4505 looks like a G-model in front, and a D - model in back..........................................  .......................................................................... So what happen was, someone got pissed at the G and drove a D- model up it's ass........

Posted by DogHouse

at 8:35 PM EDT

Updated: Thursday, 28 April 2005 8:42 PM EDT

Newer | Latest | Older

|

..........................................................................So what happen was, someone got pissed at the G and drove a D- model up it's ass........

..........................................................................So what happen was, someone got pissed at the G and drove a D- model up it's ass........